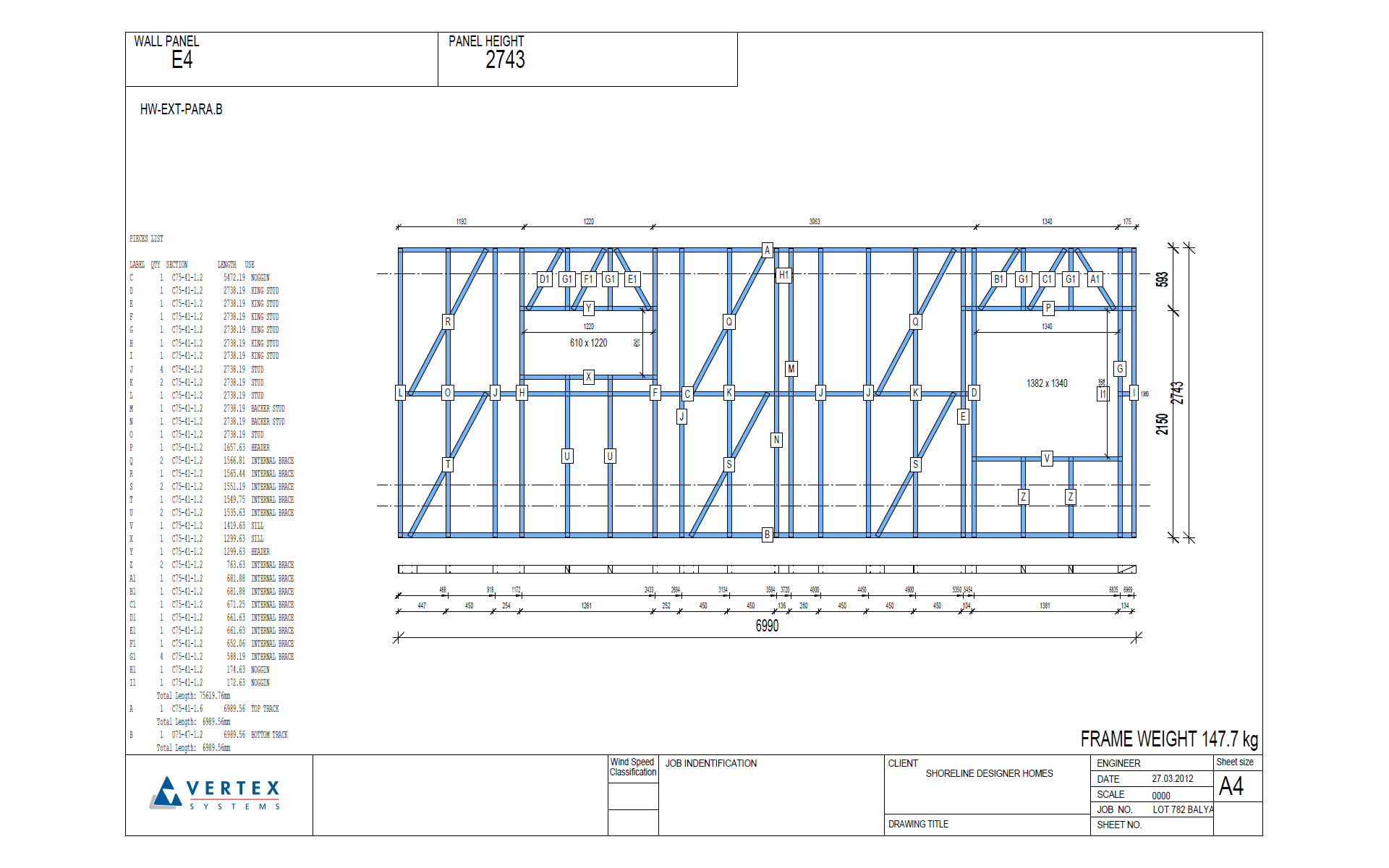

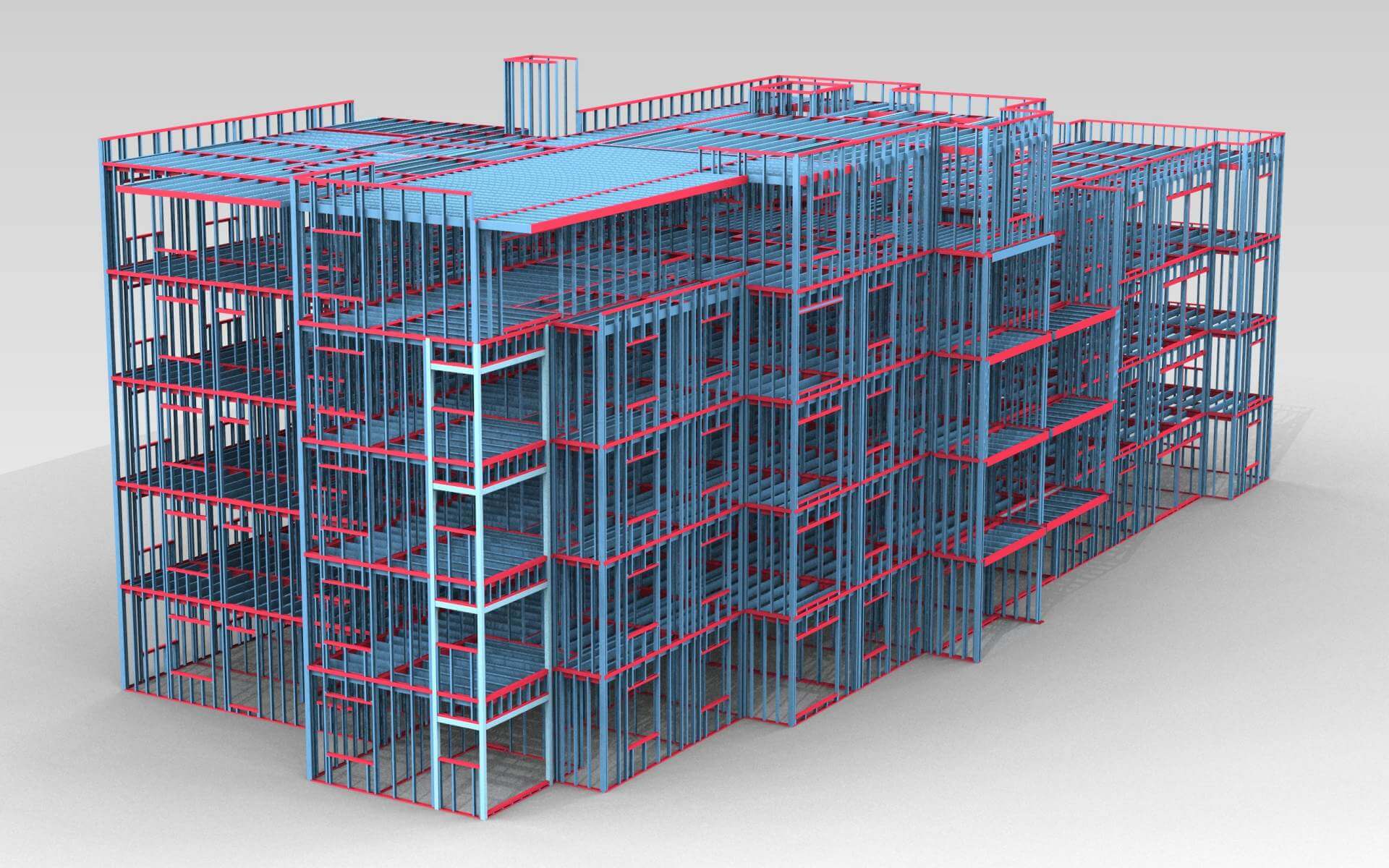

On job sites, cold-formed steel is easy to carry – lighter than wood – and doesn’t require specialized crews to mount, saving both time and money. With all work prior to installation accomplished offsite, there is a significant reduction in waste. Access for integration into mechanical and electrical systems is stamped in the steel during the production process. It works well for single-storey structures, such as commercial plazas, and excels for mid-rise buildings such as hotels, dorms and retirement homes.īuilders can also receive significant cost savings in builders’ insurance with cold-formed steel due to its non-combustible properties.Ĭold-formed steel fabrication is performed offsite and results in extremely accurate measurements with an end product of consistent quality. Let’s begin with a new advantage that as of fall and winter 2020 has never happened: cold-formed steel is now the same price or even lower in cost than lumber! Because of the popularity of wood in home renovations, patios and fences, the construction industry has been caught in a situation where customers are paying significant premiums to complete their home renovation projects.Īlong with the benefit of low cost, architects and designers will find that they have much more flexibility with cold-formed steel since it can span large rooms and bear a greater load. This newer construction material has a long list of advantages. Lumber is also easier to produce than some alternatives and requires less manufacturing energy. The renewability of wood makes it seem more of an ‘earth-friendly’ option for architects and builders who need short-term cost reductions. Wood is also beautiful, often used as design elements in commercial and residential construction. It’s familiar to everyone, and surrounds us in our homes. Wood has been used as an integral part of construction projects since the dawn of mankind. The same is true for fire-stopping information – the earlier, the better.Ĭold-formed steel is custom made for your unique project and requires longer lead times – but is the extra wait worth it? Some owners don’t confirm window placements until after the building is up, but since cold-formed steel is pre-fabricated, this information would be needed much earlier. Since cold-formed steel is pre-fabricated, it requires architects to approve designs earlier than what they may be used to. Ideally cold-formed-steel Framing in the mid-rise industry is used for 4- 12 storey’s but improvements and technologies are always advancing to take this to greater heights Many architects and builders have not yet fully considered cold-formed steel as they are more comfortable using wood.

Cold-formed steel disadvantagesĬompared to wood construction, cold-formed steel is a relatively new structural option, having only been in approved use since the mid-1900s. The materials cost for a home could rise significantly more than you (or your client) are willing to pay. Lastly, if you’ve tried to purchase even a single length of 2×4 recently, you will know that the price of wood has skyrocketed to levels never seen before. Wood joists are heavy, especially for longer spans, and may result in higher trade expenses with additional individuals being brought onboard or lost time due to injury. Once delivered to building sites, wood construction can create unnecessary and dangerous burdens to construction crews who are striving to deliver superior results under tight time constraints. It can also be a home to dangerous moulds, fungi, and insects (such as termites and carpenter ants). Rotting is always a concern with wood, which results from moisture coming in contact with it. Wood is an imperfect naturally sourced material that can have undesirable qualities, making its use as a reliable, effective and long-term construction material controversial. Let’s take a look at which one is best for your next project. This may seem obvious to many, but it’s important to familiarize ourselves with the advantages and disadvantages of different materials, especially when it comes to the fundamental structure of buildings.Ĭold-formed steel and wood are two popular construction materials used in low- and mid-rise buildings. Architects and builders beware – not all building materials are created the same.

0 kommentar(er)

0 kommentar(er)